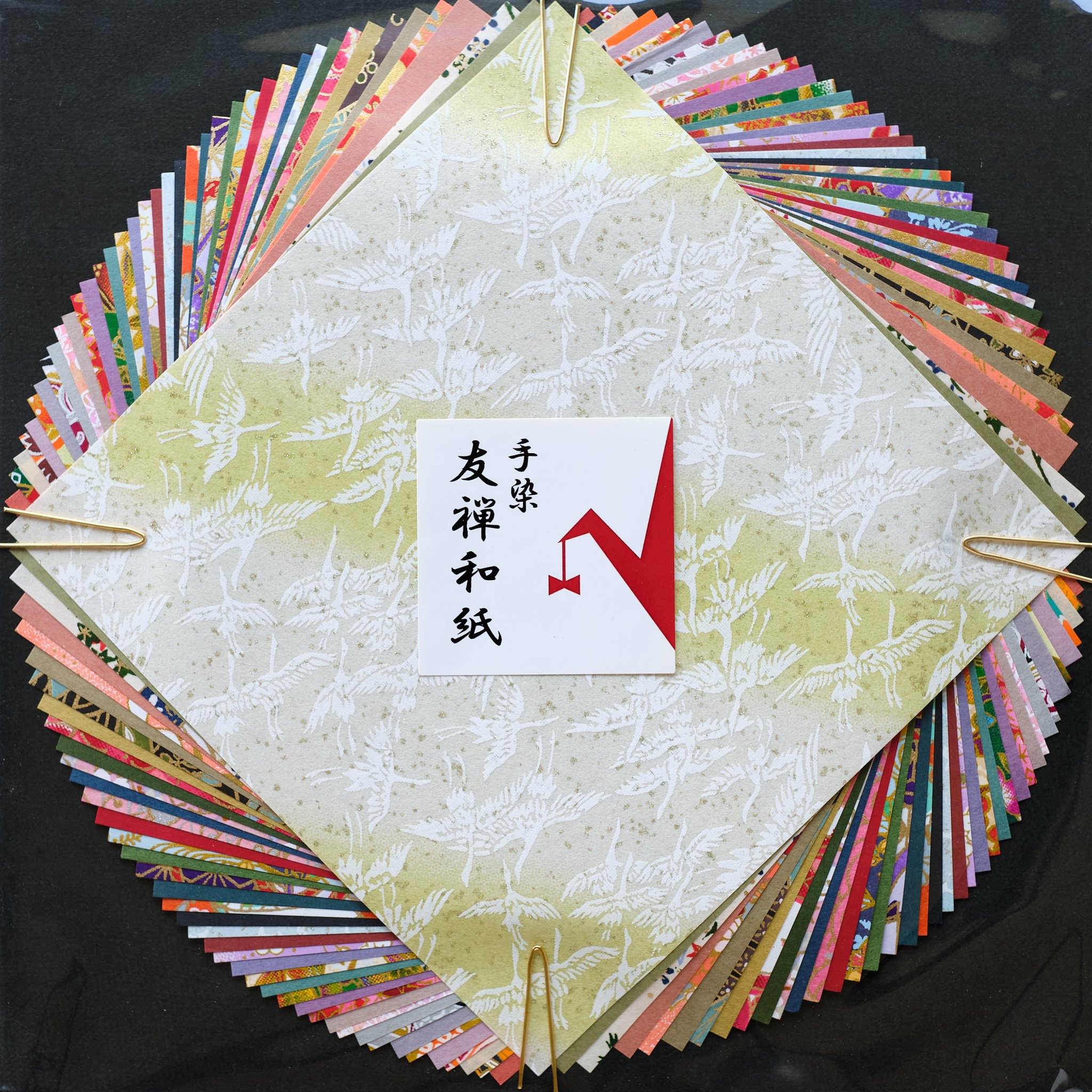

Yuzen Chiyogami

Classic Japanese craftsmanship

Japan, early 1700s

History

Chiyogami are hand-crafted decorative papers that trace their origins to Japan’s first urban centres in Kyoto and Osaka in the early 1700s. By the last half of that same century, the first monochrome images produced by woodblock printing had progressed to multi-coloured patterns executed by leading artists and master craftsmen of the day.

Although an extension of classic Japanese textile arts, Chiyogami papers were never intended to be a form of artistic expression; rather, they were consciously designed to serve practical decorative, functional and commercial purposes including toy-making and manufacture of boxes, cases, folders, envelopes and other containers.

Unlike wrapping papers meant to be used once and thrown away, chiyogami were always intended for ongoing daily use and thus made to be strong, firm and durable. For example, as when used in origami paper folding, they must be fine enough for precision folding yet strong enough not to disintegrate when paste is applied.

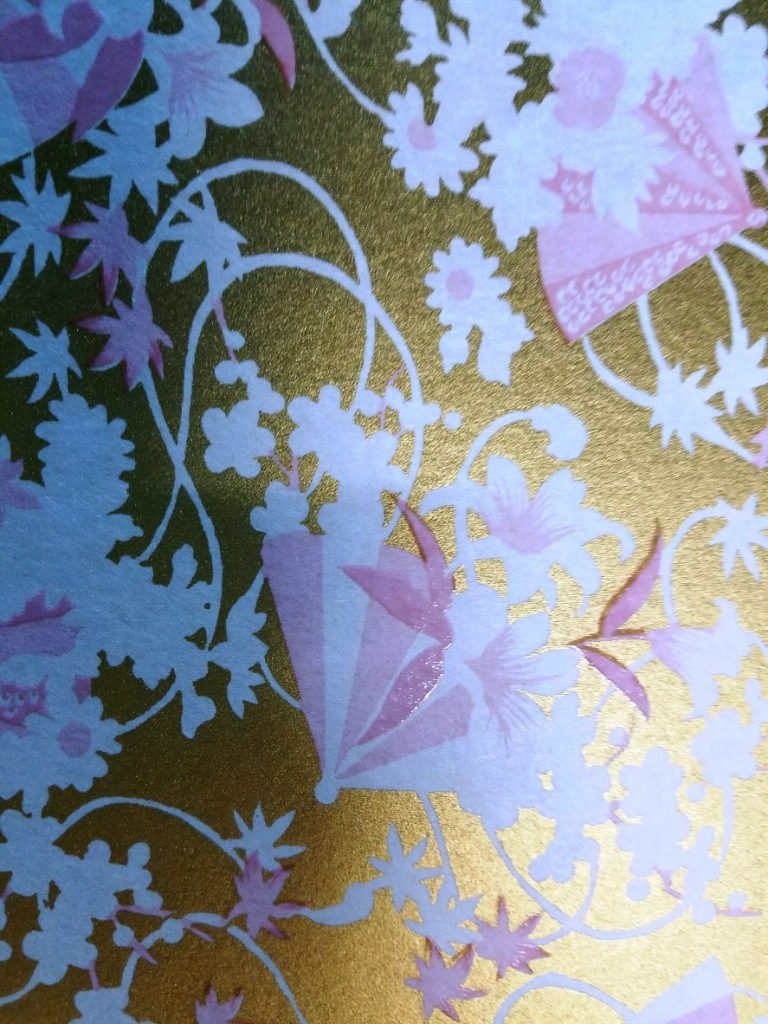

That the papers are also visually attractive is a triumph of form following function. In every era of chiyogami production, there has always been an evolving core of stock motifs, themes and accepted composition styles supplemented by newer designs developed in accordance with changing fashions and tastes.

How Chiyogami is made

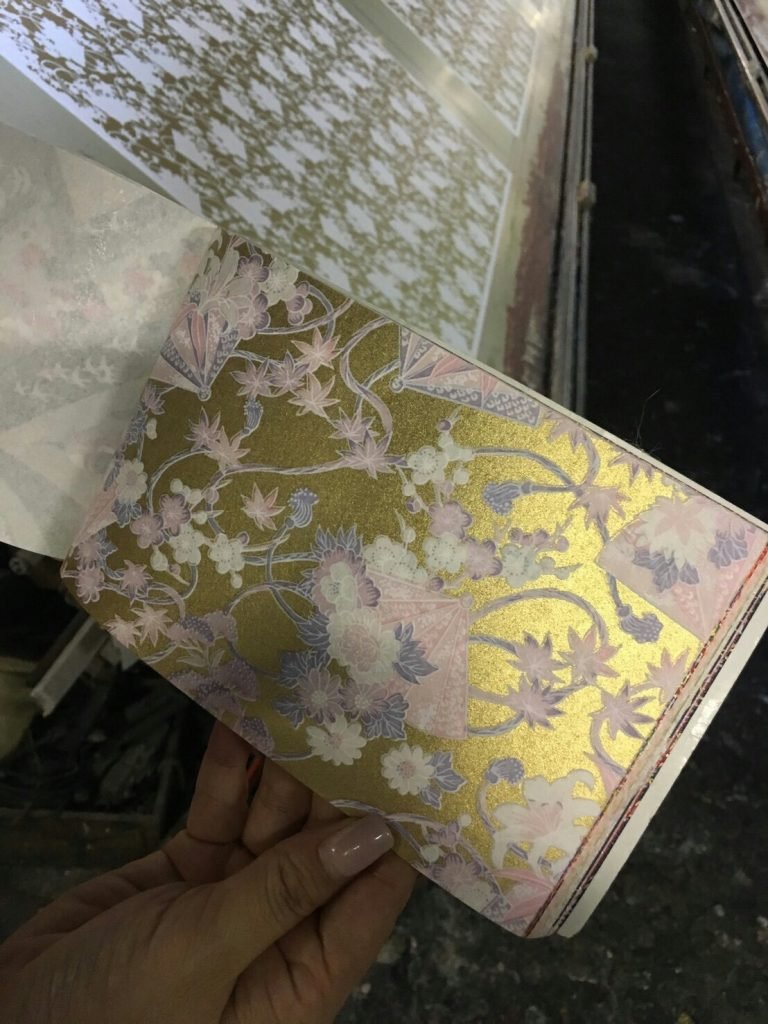

Each sheet of the Chiyogami is meticulously produced by hand, with individual applications of ink colours silkscreened through careful and precise registration.

Step 1

Base dyeing process

First, the jizome process is performed to dye the undercoat of the entire Japanese paper.

At this time, the base is dyed with a brighter and brighter "chemical gold" specification.

Step 2

Colouring process

Next, the “irozashi” process of dyeing using a formwork is performed.

The pattern inside the mold is made of silk, and it is also called the "silkscreen".

Step 3

Repeating process

Repeating the process for the number of colours it takes a lot of time and effort and multiple molds, but the result is a colourful pattern that cannot be found in inkjet printing.

Step 4

Drying process

Approximately 25 sheets of paper are dried in one unit with a stainless steel and hot air in about 10 minutes.

It is dry from below and above.

And the hand-dyed Chiyogami paper is complete!

Traditional chiyogami production continues to be carried out in several cities in Japan. Chiyogami offered by Ibis are sourced from Kadokawa Papers in Osaka, established 1904

Our Chiyogami

At this time we are able to offer origami sets of 40 pieces each (20Chiyogami and 20 pieces solid colour), all precision cut to 150x150 mm.

Full sheets (940x640 mm) and half sheets are also available.

Chiyogami Journal

Our Chiyogami Journals are silk cover in Black Brocade from Obi (Kimono Sash), delicately finished with Chiyogami

end-papers